Spécialiste de l'inox depuis 1989

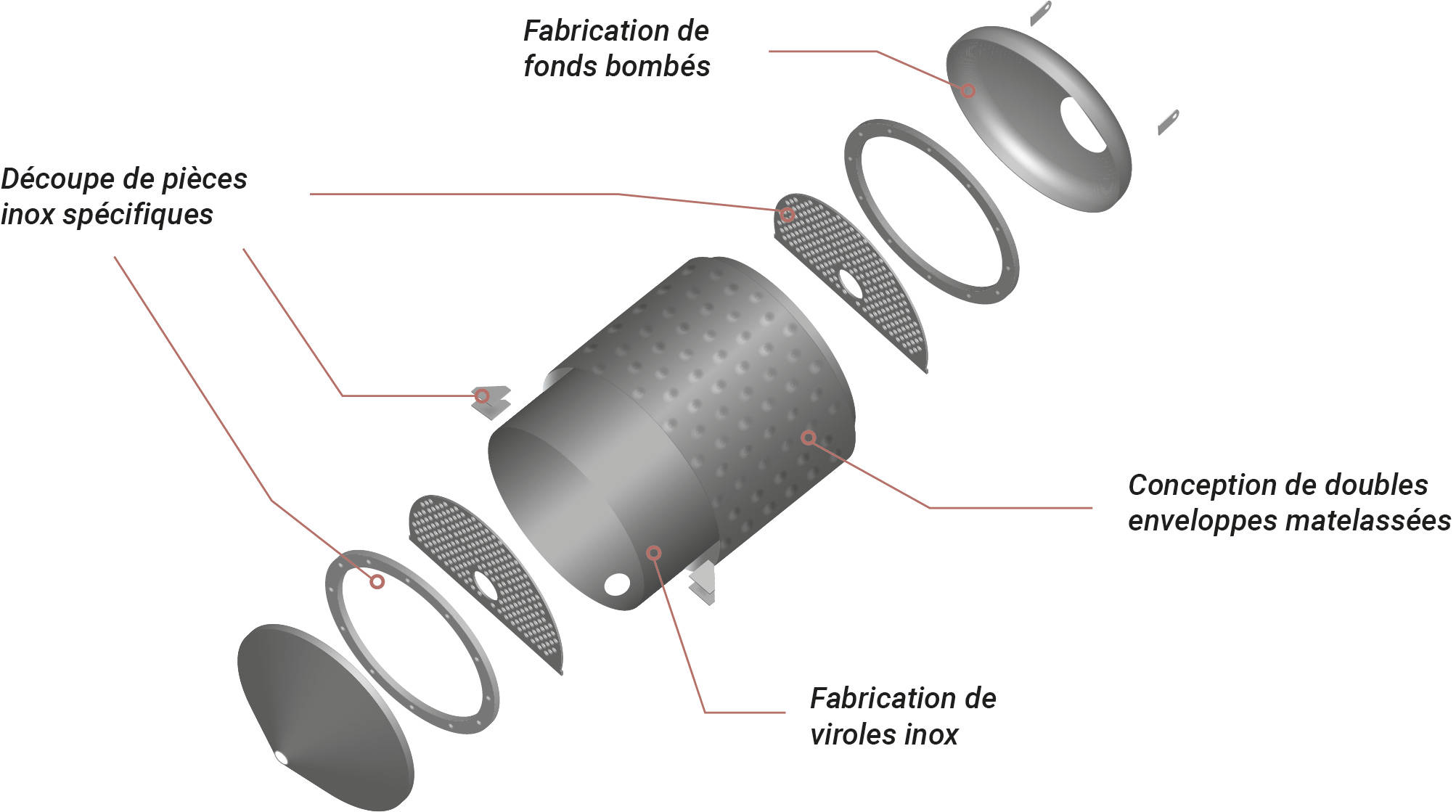

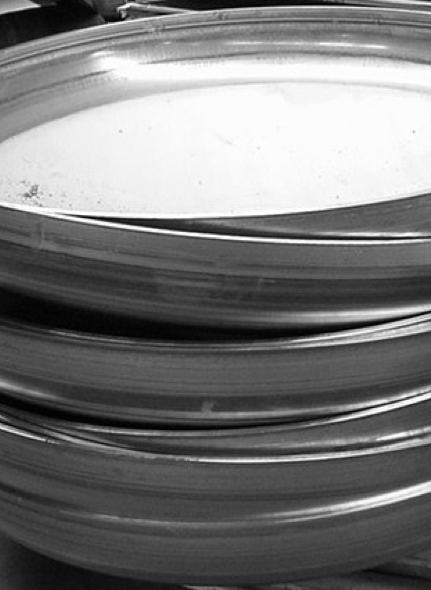

DVAI fabrique depuis 1989 les différentes pièces de vos cuves inox comme les découpes spécifiques, les fonds bombés, les viroles et les enveloppes matelassées

4 activités pour répondre à tous les besoins

Depuis 1989, nous continuons de faire évoluer notre expertise de l’inox à travers nos différentes activités comme la découpe inox, la fabrication de fonds bombés et de viroles inox ainsi que le développement des doubles enveloppes matelassées pour améliorer les échanges thermiques.

Découpe industrielle

Fond de cuve

Virole

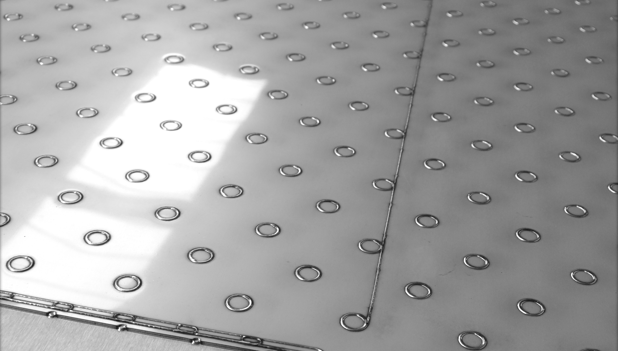

Enveloppe matelassée

35 ans d'expertise

Découpe express

Fonds bombés en 48H

Un service de qualité

L'expertise pour chacun de nos clients.

Pétrochimie

La pétrochimie est devenue un acteur majeur de l’économie et de la société d’aujourd’hui.

Chimie

L’activité chimique transforme les matières premières naturelles de la terre, la mer et l’air.

Pharmacie

L’industrie pharmaceutique développe, produit et commercialise des médicaments ou des produits pharmaceutiques.

Agroalimentaire

L’industrie alimentaire, aussi appelée « industrie agroalimentaire » (IAA) représente la totalité des activités industrielles

Bâtiment

Le secteur du bâtiment développe énormément de constructions basées sur le métal. Plus d’informations sur nos réalisations sur notre site dédié : Dvai bâtiment

Spécialiste du fond bombé et du fond de cuve

DVAI fabrique suivant la NFE81100 fond GRC, fond PRC, fond MRC, fond elliptique avec des prestations de polissage et de découpe des ouvertures pour les piquages. DVAI fabrique virole pour cuve inox, cone et fond conique.

Un stock de tôles inox permanent pour des délais courts

Un stock permanent de 1 000 tonnes de plaque et tole en Inox et Aluminium incluant + de 10 nuances différentes (inox 304L – inox 316L – inox 321 – inox 316Ti – UB6 / 904L – inox réfractaire 310 S – duplex UR45N – duplex UR35N – Aluminium 5754 – Aluminium 5083 ) nous permettent de répondre instantanément à la demande de nos clients.