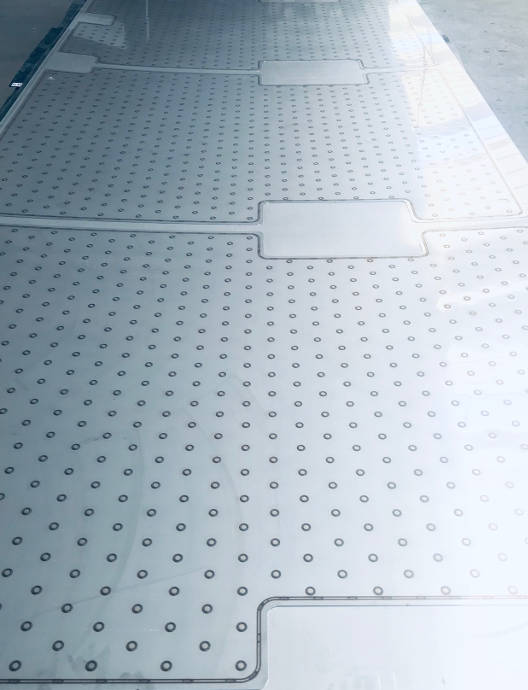

Pillow plated rolled shell

DVAI manufactures pillow plated rolled shells thanks to our laser welding machine. These shells can be used in order to make a full tank or a stainless steel reactor.

Pillow plates proposed by DVAI

- DVAI supplies the pillow plates

- DVAI rolls and welds jacketed barrels

The pillow plated barrels are perfectly adapted in food and beverage applications (winemaking tanks, fermenters for beer…), chemical industry (reactors, temperature maintenance tanks for heating and cooling processes). This reliable and simple solution has been imposed in all kinds of industries worldwide.

There are 3 kinds of possible applications:

- Heating (stem)

- Cooling (frozen water, glycol and freezing agents)

- Temperature maintenance

The reliability of the spot welding assembly assures an optimal result.

Manufacturing steps

After reception and validation of an order, the technical office designs a drawing presenting:

- the shape of the two plates (metal base sheet and the pillow plate sheet)

- the positioning of IN and OUT hole connections for heat transfer fluid

- the welded spots pattern

- eventual continuous welded lines for mastering the circuit

This drawing is submitted to the client for validation

Manufacturing starts immediately after the client’s agreement enabled by DVAI’s complete stock of plates as well as all the machines necessary for the cutting.

Pillow plates are delivered non-inflated along with the installation notice for the in and out connections and helpful advice for inflating and eventual repairing.

DVAI supplies pillow plated barrels by laser welded spots for your storage vessels, fermenters and stainless steel reactors

Pillow plate advantages

Our pillow plated rolled shells has several advantages :

- Cost effectiveness of implementation

- Excellent exchange coefficient

- Slight volume of inside pillow plates